Типы днищ

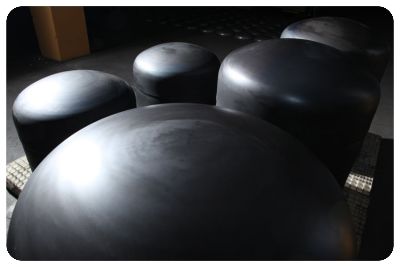

Фото днищ

Polukarova bottoms

PC Boiler has the ability to produce polushariya (hemispherical) bottom from 500 mm to 12000 mm. Polukarova bottoms can have a thickness from 1.5 mm to 250 mm. usually, this type of bottoms are used for machines of large diameter, as these bottoms are easier to produce than elliptical with a flare. Hemispherical bottoms are made of separate stamped components: ball segment and ball of petals, which are further welded to each other in normals. Unfortunately, not many factories in Russia have the opportunity to make this type of bottoms, because bottoms polukarova difficult to manufacture, but their increased cost of manufacture kompensiruet a savings in metal with their use in large vehicles.

PC Boiler has the ability to produce polushariya (hemispherical) bottom from 500 mm to 12000 mm. Polukarova bottoms can have a thickness from 1.5 mm to 250 mm. usually, this type of bottoms are used for machines of large diameter, as these bottoms are easier to produce than elliptical with a flare. Hemispherical bottoms are made of separate stamped components: ball segment and ball of petals, which are further welded to each other in normals. Unfortunately, not many factories in Russia have the opportunity to make this type of bottoms, because bottoms polukarova difficult to manufacture, but their increased cost of manufacture kompensiruet a savings in metal with their use in large vehicles.

PC Boiler offers bottoms of their own making, and production of European plants. Delivery from Europe is carried out 1 time per month.

PC Boiler has the ability to produce a hemispherical bottom type of double-layer steel (the core layer of carbon steel, a plating - of any other material). This is useful if the thickness of 30 mm, because otherwise the savings on the cost of material is reduced to zero due to the high cost of making a two-layer steel. Typically, our clients apply polukarova bottoms with thickness equal to the thickness of the cylindrical body, because they are easy separate, as well as reducing additional edge stresses.

d = 8000 mm.

at T = 250 mm.

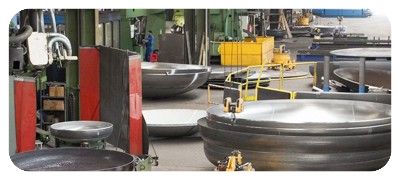

Technical capabilities of our partners in Europe

- production of bottoms up to 8000 mm in diameter and wall thickness up to 250 mm;

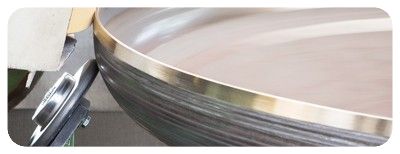

- Plasma cutting of metal up to 80 mm thick and gas flame cutting of walls up to 300 mm thick;

- submerged arc welding / plasma welding of round sheet blanks up to 9000 mm in diameter;

- welding bottoms up to 150 tons in weight from individual segments using a circular manipulator;

- electroslag cladding of bottoms with a diameter of up to 8000 mm;

- plasma gas-plasma cutting of holes with robotic control and 3D modeling, including preparation of the bottom edge to 6200 mm in diameter and 80 mm in the wall thickness by plasma cutting, and 200 mm in the wall thickness with gas flame cutting;

- Surface treatment: shot blasting (steel shot, granulated crumb, glass granule), etching / passivation grinding of bottoms up to 8000 mm in diameter;

- Saw processing: machining in diameter up to 2700 mm; gas-flame cutting plus grinding in diameter up to 8000 mm;

- thermal treatment of the bottoms: normalization, stress relief, softening, hardening followed by tempering up to 8000 mm;

- quality control of metals by non-destructive testing: X-ray, ultrasound, color, magnetic-powder flaw detection.